UMD Loop

Overview

I am the current Lead Mechanical Engineer for UMDLoop, an entirely undergraduate run engineering club focused on designing complex systems to compete in engineering competitions. So far, the team has competed in SpaceX's Hyperloop Competitions from the beginning as well as now working on engineering design for The Boring Company's Not-A-Boring competitions. My responsibilities include the overseeing of a large group of mechanical engineers designing complex static, dynamic, hydraulic, and soil structures with an emphasis on reliability and in house manufacturing and assembly. I also hold responsibilities for designing, verifying, procuring, a integrating systems such as a hydraulic steering system, ALPS, and the test track.

Skeleton Subsystem Lead

Led a team of engineers developing structural elements of UMDLoop's tunnel boring machine in the first Not-A-Boring competition in Las Vegas. Led the integration and structural support and manufacturing during the week of competition. This included tasks such as on site manufacturing, lifting hand calculations and deflection FEA, heavy lift coordination, and testing.

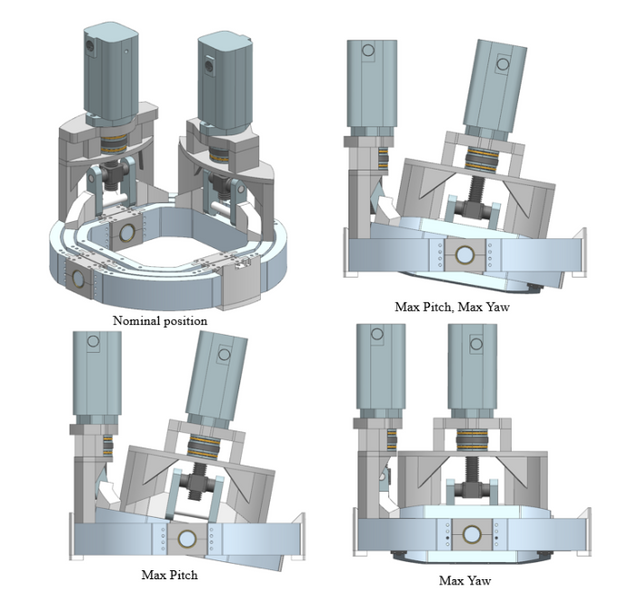

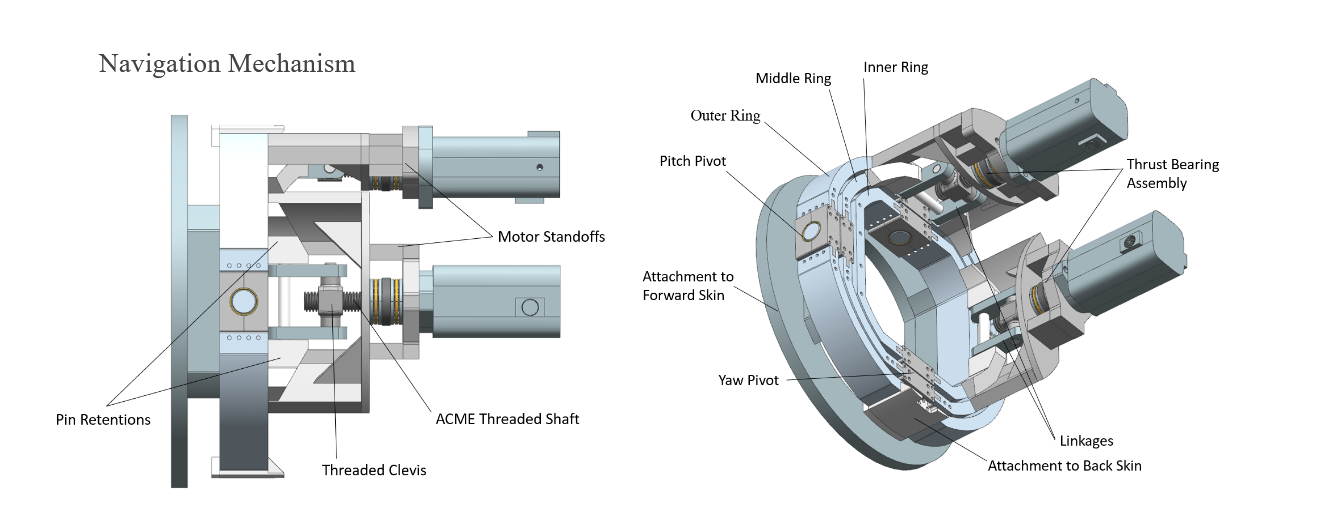

Led the design, analysis, procurement, assembly, and testing of a hydraulic 2 degree of freedom open centered steering system capable of producing ~200,000 in-lb of torque and support a pipe jacking force of 60 kip. This steering system was fully integrated and hooked up, but was not used on site due to a change of rules and time constraints leading to our operations necessitating a straight path. More on the design and analysis in the next section.

Not-A-Boring Competition Steering

The first Not-A-Boring competition was announced at the beginning of the Fall 2020 semester during the middle of the pandemic. Before this, my engineering team had been itching to continue working, designing, and learning about engineering after the lack of SpaceX's hyperloop competition 5 rules. Naturally, when the new competition by a sister company was announced, we jumped at the opportunity and started research immediately. As a team comprised mostly of Aerospace Engineers designing to low safety factors in aluminum, we began work on our new steel tunnel boring machine and learning how to work with soil calculations. We had less than 4 months to go from knowing nothing about tunnel boring to having a finalized design and PDB submitted. We successfully became one of 12 teams selected out of nearly 400 applicants and one of 4 teams approved to dig on competition day.

My role on the team began as a team member working on calculations for the main bulkheads and weld joints. I quickly moved into the Skeleton Lead position as our lead had to step down. During this time I had proposed a new 2 degree of freedom steering system to our Lead Mechanical Engineer and from there I took over as lead for both the Skeleton and Steering subsystems. I developed many important skills in CAD modeling and design for manufacturing using Siemens NX. I also utilized NASTRAN to perform Finite Element Analysis to verify hand calculations for lifting calculations, the full steering system, and many other structures such as the skin, bulkheads, and back-plates. What resulted was a functioning critical steering system capable of producing 20kN-m of torque and support an axial force of 60 kip. In this position, I successfully deployed a functioning steering system as well as creating many formal testing, system validation, and operations documents to accompany this design.

SpaceX Hyperloop Test Track

During our time after competition 4, and in anticipation of a competition 5 rule set, 2 other people and I designed a simple test track for the teams competition hyperloop pod. This test track was created to support short range full system tests and operations over a 25 foot distance and designed for modularity so we could expand to longer if needed. I utilized Siemens NX and NASTRAN FEA to analyze and verify hand calculations in I-beam stresses and deflections. I machined and assembled the entire test track in house and was in the process of performing full system testing on it prior to the Covid-19 pandemic and the newly released rules for the next competition from The Boring Company.